Equipment Overview

The ” Super Burn ” electric furnace, which uses a molybdenum disilicide heater and high-quality alumina board insulation, has earned a high reputation and trust as a synonym for fast heating electric furnaces. The furnace is highly reliable and can be used with confidence thanks to the non-contact sequence. Customized furnace inner dimensions are available. The “High-Temperature Furnace” is a high-temperature electric furnace with a proven track record in various fields as a furnace for heat treatment and baking at high temperatures.

Features

- High-quality alumina boards are used for thermal efficiency and excellent insulation

- Sequence circuits have been made as contactless as possible, greatly improving reliability.

- 19-pattern program controller for optimum control to suit the sample.

- Safety design with over-temperature protector, double-winding transformer, outer wall cooling, etc.

- Operation panel, one-touch door, and other user-friendly features

- Furnace stand type control panel saves space (except for large type)

option

- Gas introduction device (two types with and without flow meter)

- Gas Exhaust

- deodorizer

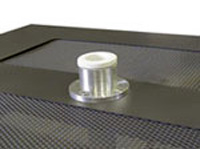

(Electric furnace ceiling)

(with flow meter)

| Electric Furnace Outline Specifications | |||

| Model | NH-2045D | NH-3035F | NH-3045F |

| Dimensions (including control unit) W x H x D mm |

490×1400×750 | 700×1650×850 | |

| Inner dimensions of furnace W x H x D mm |

200×200×450 | 300×300×350 | 300×300×450 |

| Primary power supply | AC200V single phase 50/60Hz | ||

| Equipment power | 11kVA | 12kVA | 14kVA |

| Heater capacity | 9.5kW | 10kW | 12kW |

| Normal operating temperature | 1700°C | ||

| Maximum temperature | 1700°C | ||

| Temperature rise time | Approx. 1Hr/1700°C | Approx. 4Hr/1700°C | |

| Temperature distribution | Approx. ±5°C (at 1700°C within the effective dimension) | ||

| Atmosphere | Oxidizing atmosphere (in air) | ||

| Heating element | Molybdenum disilicide ( MoSi2 ) | ||

| Control method | Programmed PID continuous control method, 1-zone control | ||

| Control section | Furnace stand panel | ||

| Electric Furnace Outline Specifications | ||||||

| Model | NH-3050F | NH-3060F | NH-3550G | |||

| Dimensions (including control unit) W x H x D mm |

700×1650×850 | 1000×1650×1000 | 750×1650×900 | |||

| Inner dimensions of furnace W×H×D mm |

300×300×500 | 300×300×600 | 350×350×500 | |||

| Primary power supply | AC200V single phase 50/60Hz | |||||

| Equipment power | 14.5kVA | 18kVA | 18kVA | |||

| Heater capacity | 13kW | 15kW | 15kW | |||

| Normal operating temperature | 1700°C | |||||

| Maximum temperature | 1700°C | |||||

| Temperature rise time | Approx. 4Hr/1700°C | |||||

| Temperature distribution | Approx. ±5°C (at 1700°C within the effective dimension) | |||||

| Atmosphere | Oxidizing atmosphere (in air) | |||||

| Heating element | Molybdenum disilicide ( MoSi2 ) | |||||

| Control method | Programmed PID continuous control method, 1-zone control | |||||

| Control section | Furnace stand panel | |||||

| Electric Furnace Outline Specifications | |||||

| Model | NH-4060H | NH-4080H | NH-5080J | ||

| Dimensions W x H x D mm |

900×1700×1070 | 900×1700×1170 | 1040×1800×1270 | ||

| Inner dimensions of furnace W×H×D mm |

400×400×600 | 400×400×800 | 500×500×800 | ||

| Primary power supply | AC200V 3 phase 50/60Hz | ||||

| Equipment power | 29.5kVA | 38kVA | 55kVA | ||

| Heater capacity | 25kW | 34kW | 46kW | ||

| Normal operating temperature | 1700°C | ||||

| Maximum temperature | 1700°C | ||||

| Temperature rise time | Approx. 4Hr/1700°C | ||||

| Temperature distribution | Approx. ±5°C (at 1700°C within the effective dimension) | ||||

| Atmosphere | Oxidizing atmosphere (in air) | ||||

| Heating element | Molybdenum disilicide ( MoSi2 ) | ||||

| Control method | Programmed PID continuous control (3-zone control) | ||||

| Control unit | Stand-alone panel (not included in the above dimensions) | ||||