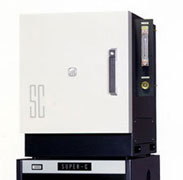

Equipment Overview

Super C series electric furnaces are energy-saving electric furnaces using silicon carbide heating elements and high-purity alumina board for insulation,

It is a fast heating furnace that raises the temperature to the normal maximum temperature of 1500°C in about 60 to 120 minutes. The furnace is equipped with a high-function digital program controller as standard equipment for temperature control, improving functionality, operability, and reliability. This furnace can be used for a wide range of heat treatment applications, from R&D to small lot production.

Features

- Extremely fast temperature rise rate; temperature can be raised to 1,500°C in about 60 to 120 minutes.

- High purity alumina board used for excellent thermal insulation

- 19-pattern program controller for optimum control to suit the sample.

- Over-temperature protector, thyristor error alarm, outer wall cooling, etc. are standard features for safety and peace of mind.

- Operation panel, one-touch door, and other user-friendly features

- Furnace stand type control panel saves space. (except large type)

option

Deodorization device

Gas introduction mechanism (two types with and without flow meter)

Gas exhaust hole

Temperature measurement hole inside the furnace

(Electric furnace ceiling)

(with flow meter)

| Electric Furnace Specifications | |||

| Model | SC-2025D | SC-2035D | SC-2045D |

| Inner dimensions of furnace W x H x D mm |

200×220×250 | 200×220×350 | 200×220×450 |

| External dimensions (including control unit) W x H x D mm |

510×1550×700 | ||

| Primary power supply | AC200V single phase 50/60Hz | ||

| Equipment power | 11kVA | 12kVA | 15kVA |

| Heater capacity | 9kW | 10kW | 12kW |

| Normal/max. temperature | 1500°C | ||

| Temperature rise time | Approx. 60 min/1500°C | ||

| Temperature distribution | Approx. ±5°C (at 1500°C within the effective dimension) | ||

| Atmosphere | Oxidizing atmosphere (in air) | ||

| Heating element | Silicon carbide heating element | ||

| Control method | Programmed PID control | ||

| Control unit | Space-saving furnace base type panel (with temperature recorder) | ||

| Electric Furnace Specifications | |||

| Model | SC-3035F | SC-3045F | SC-3550G |

| Inner dimensions of furnace W x H x D mm |

300×320×350 | 300×320×450 | 350×350×500 |

| External dimensions (including control unit) W×H×Dmm |

680×1700×680 | 680×1700×780 | 900×1850×1000 |

| Primary power supply | AC200V single phase 50/60Hz | ||

| Equipment power | 12kVA | 17kVA | 23kVA |

| Heater capacity | 9.3kW | 13kW | 18kW |

| Normal/max. temperature | 1500°C | ||

| Temperature rise time | Approx. 120 min/1500°C | ||

| Temperature distribution | Approx. ±5°C (at 1500°C within the effective dimension) | ||

| Atmosphere | Oxidizing atmosphere (in air) | ||

| Heating element | Silicon carbide heating element | ||

| Control method | Programmed PID control | ||

| Control unit | Space-saving furnace base type panel (with temperature recorder) | ||

| Electric Furnace Specifications | |||

| Model | SC-4060H | SC-4080H | |

| Inner dimensions of furnace W x H x D mm |

400×400×600 | 400×400×800 | |

| Primary power supply | AC200V three-phase 50/60Hz | ||

| Equipment power | 26KVA | 35KVA | |

| Heater capacity | 22.5KW | 30KW | |

| Normal/max. temperature | 1500°C | ||

| Temperature rise time | Approx. 180 min/1500°C | ||

| Temperature distribution | Approx. ±5°C (at 1500°C within the effective dimension) | ||

| Atmosphere | Oxidizing atmosphere (in air) | ||

| Heating element | Silicon carbide heating element | ||

| Control method | Programmed PID control | ||

| Control unit | Separate installation: Free-standing panel (with temperature recorder) | ||