Equipment Overview

Since its launch in 1975, the fast heating electric furnace ” SUPER BURN ” has been highly evaluated and trusted, and has become a best-selling product with more than 3,000 units sold.

The S6/S7 series has been developed to improve the furnace construction method and ease of use, and features improved temperature distribution accuracy, approximately 20% less power consumption, an intuitive touch panel for easy operation, and a separate electric furnace and control unit for more flexible installation layout.

Features

- Energy-saving design (approx. 20% less than our conventional products)

The use of high-quality alumina board insulation and improved furnace construction methods have resulted in improved thermal efficiency and higher economic efficiency. - CO2 emissions (approx. 20% reduction compared to our conventional products)

S6-2025D reduces CO2 emissions by approx. 452 kg/year. (Other models are almost the same)

Conventional model: 1.08Kg CO2/kWh New model: 0.86Kg CO2/kWh

*CO2 emission coefficient per 1kW of electric power at Kansai Electric Power Company, calculated on the assumption that the machine is operated 8 hours a day, 260 days a year (5 days/week). - Precise temperature distribution Approx. ±3°C (within effective dimension, without sample, when stable)

- Touch panel for simple operation

All operations can be performed intuitively on the touch panel. Graphical color display of necessary information. The built-in temperature program has 20 patterns/13 steps. Data collected by the monitor can be saved in the touch panel in CSV file format and transferred to USB storage memory, contributing to a paperless environment. - Safety design.

Various safety features such as over-temperature protection, thermocouples for independent over-temperature, furnace body cooling, door locking mechanism, etc. are provided. - Flexible installation

The control panel is compact and lightweight, making it possible to use either the table-top type or the furnace-bed type, in which the furnace body is placed on a special stand. This provides greater flexibility in installation and saves space.

option

Gas inlet device (2 types with/without flow meter) ○ Gas exhaust hole ○ Dedicated stand ○ Instantaneous power failure countermeasure ○ Power saving stop ○ Emergency stop ○ Door alarm ○ Temperature recorder ○ Temperature measurement hole ○ Deodorization device ○ Flange for mounting furnace core tube

(Furnace body and control unit are fastened with screws)

Data collection

Alarm display and history

Communication with USB memory

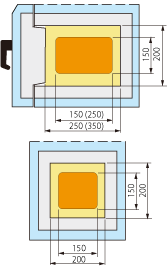

Figures in parentheses ( ) indicate S6/S7-2035

| Electric Furnace Outline Specifications | ||||

| Model | S6-2025D | S6-2035D | S7-2025D | S7-2035D |

| Max. normal temperature | 1600°C | 1700°C | ||

| Temperature distribution | Approx. ±3°C (within effective dimensions, normal temperature, at no-sample stability) | |||

| Temperature rise time (empty furnace) | Approx. 60 min | |||

| Atmosphere | Oxidizing atmosphere (atmosphere) | |||

| Furnace dimensions W x H x D mm |

200×200×250 | 200×200×350 | 200×200×250 | 200×200×350 |

| Heating element | Molybdenum disilicide ( MoSi2 ) | |||

| Heating element capacity | 6.0 kW | 7.5 kW | 6.0 kW | 7.5 kW |

| Control method | PID continuous control method | |||

| Primary power supply | AC200V 1φ 50/60 Hz | |||

| Equipment power | 9 kVA | |||

| Outer dimensions of furnace body | W490 × H625 × D670 mm | |||

| Furnace weight | Approx. 74 kg | Approx. 79 kg | Approx. 74 kg | Approx. 79 kg |

| Control unit dimensions | W300 × H625 × D670 mm (tabletop panel) | |||

| Weight of control unit | Approx. 55 kg | |||