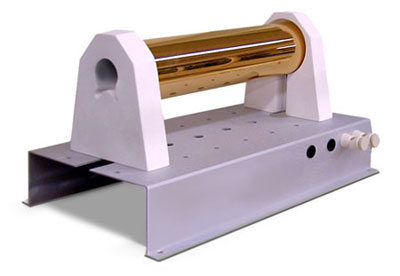

Equipment Overview

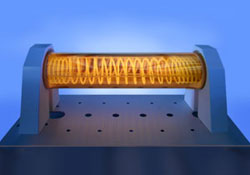

A transparent electric furnace with a thin gold coating on the inner surface of a quartz tube and a heater wound inside it reflects more than 95% of the heat radiation from the heater due to its gold mirror, thus shielding and retaining heat. Since the heat radiation from the heating element is reflected evenly and efficiently, the furnace can quickly raise the temperature with a small amount of electricity. The small heat capacity of the reflective material also provides excellent descent temperature characteristics and heating response. The inside of the furnace can be seen through the furnace at high temperatures, making it ideal for sample observation.

Features

- At high temperatures, the inside of the furnace becomes transparent and the sample can be seen.

- Compact and lightweight with a small weight to size ratio in relation to the reaction tube capacity

- Thin-film gold mirrors can easily achieve long homogeneity even with a single heating element

- Energy-saving design with good heating and heat retention characteristics.

option

- Can be produced up to 170φ x 1000mm

- Vacuum and various gas atmosphere specifications

Temperature control box

Dedicated temperature control unit is available

| Transparent Electric Furnace Specifications | |||

| Type | Type A | B Type | C type |

| Gold tube dimensions (diameter x length mm) | 81 x 305 | 81×500 | 110×500 |

| Furnace core tube dimensions (dia. x length mm) | 41×406 | 41×609 | 61×609 |

| Primary power supply | 1φ 200V 50~60Hz | ||

| Equipment power supply capacity | 1.5KVA | 2KVA | 2.5KVA |

| Maximum temperature | 900°C | ||

| Heating element | Metal heater | ||

| Control method | Voltage feedback PID control | ||