Equipment Overview

The use of superheated steam suppresses the rapid generation of pyrolysis gases and is highly effective in removing residual individual carbon components.

It contributes to time saving, energy saving, and production cost reduction in various industries.

Features

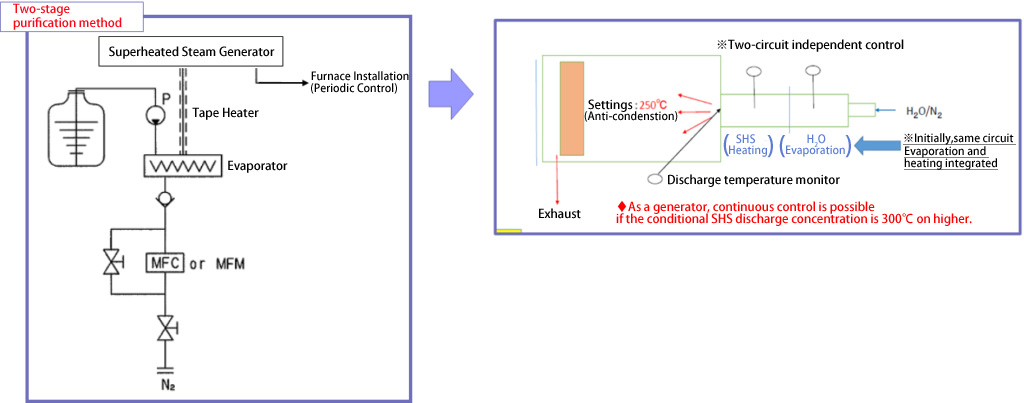

- Superheated steam heating can be programmatically controlled to match the furnace temperature, making it effective for ceramics and other products that are subject to temperature fluctuations.

- The vaporizer and superheated steam generator are combined into one unit, allowing gas to be introduced into the furnace without condensation.

- The evaporator is made of ceramic, allowing it to be used up to high temperatures.

| Equipment Specifications | |

| Temperature | 200 to 800℃ |

| Feed rate | Max 30g/min |

| Electric capacity | AC200V 4KVA |