[ NIKKATO CORPORATION Product ]

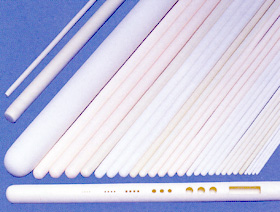

■Protection Tube, Insulating Tube, Thin Tube

Our lineup includes alumina, which can be used up to a maximum operating temperature of 1,850℃, as well as mullite, zirconia, and magnesia materials, all boasting excellent corrosion resistance.

They are suitable for use in all types of heat treatment furnaces.

■Features

- Superior heat resistance, allowing them to withstand the required high temperatures and maintain excellent gas-tightness.

- Excellent high-temperature strength and thermal shock resistance.

- Superior creep resistance, resulting in minimal change at high temperatures.

- Chemically stable and highly corrosion resistant.

- Low dielectric constant and excellent electrical insulation properties.

- Good temperature responsiveness.

■Size

One-end sealed Protection Tube

Range(O.D. x I.D.): φ3 x φ2 to φ30 x φ24 mm

Maximum length: 2000 mm

Insulating Tube and Thin Tube

Range(O.D. x I.D.): φ1.2 x φ0.8 to

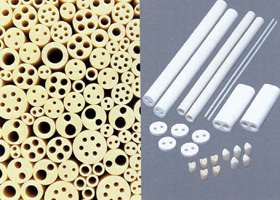

*Please consult us regarding custom lengths and the number of bores.

■Material

- Mullite

HB, S(Chamotte) - Alumina

SSA-S - Zirconia

CaO-ZrO2 system, ZR-11, Y2O3-ZrO2 system, ZR-8Y, YSZ-8

Main applications

- Gas injection tubes, gas sampling probes

- Protective and insulating sheaths for temperature-measuring thermocouples and various equipment

- Jig materials for supporting components

*We also accommodate various hole machining and grinding/lapping processes.

*Alumina -coated products(Al-SSA) are also available for alumina protective tubes to improve thermal shock resistance.