[NIKKATO CORPORATION Product]

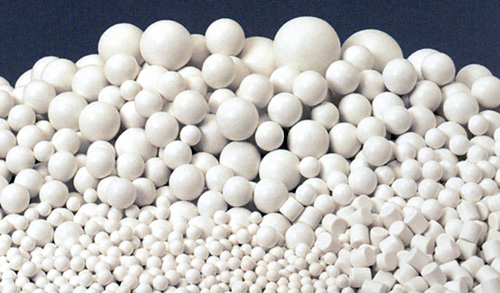

Wear-Resistant Ceramics: Alumina Balls for Milling, Dispersion, and Mixing

Alumina Ball

Our alumina balls for milling, dispersion, and mixing feature high hardness and toughness, coupled with extremely low wear loss, making them suitable for use in various mills, including pot mills, ball mills, vibration mills, and planetary ball mills.

To maximize the efficiency and effectiveness of these milling machines, the media must possess the following characteristics:

High hardness and impact strength.

High specific gravity

Low wear rate

Features

- HD Alumina Ball/Cylinder

These products offer excellent wear resistance and are widely adopted across various industries for fine milling, dispersion, and mixing. - HD-11 Alumina Ball

These offer especially low wear and long service life, making them ideal for milling highly hardened materials. - HD-2 Alumina Ball

Featuring excellent chipping resistance, these balls are primarily suited for dry milling applications. - SSA-995 High Purity Alumina Ball

These are effective for milling industrial ceramics and electronic component materials where purity is critical, especially minimizing contamination by impurities other than alumina. - SSA-999W High Purity Alumina Ball

These offer extremely low wear and a long lifespan. The minimal abrasion powder generated is exceptionally fine, ensuring virtually no contamination by non-alumina components.

Main applications

- Milling and dispersion of glass raw materials.

- Milling and mixing of cement.

- Milling and dispersion of pigments.

- Milling of ceramic raw materials.

Size