80 years of experience in the sale of electric furnaces, dryers, control devices, environmental testing equipment, and hydraulic equipment

Ignite the dreams of the near future with thermal application technology

Supporting the development of new materials and new products

Testing Center

Our test center is located in a separate building adjacent to our main factory in Hirakata City, Osaka Prefecture.

We have over 30 testing machines and various utilities to help our customers accelerate the development of new materials and products.

We can handle a wide range of needs, from prototyping and experimental stages to production simulations.

Our dedicated test center staff will assist you with your testing, so please feel free to contact us for more information.

Supporting the Advancement of Cutting-Edge Technologies

Evaluation, Thermal Measurement, Control & Monitoring Instruments, Heat Exchangers, and Filters

Motoyama Co., Ltd. is one of Japan’s leading distributors of industrial equipment, including reliability testing instruments, thermal measurement devices, hydraulic filters, and heat exchangers.

With a long history of proven performance, we supply a wide range of high-quality products that form the foundation of modern manufacturing.

Our knowledgeable and technically skilled sales engineers provide optimal solutions tailored to each customer’s unique challenges and requirements.

Through reliable technical expertise and responsive service, we have earned the trust of numerous companies across diverse industries.

Filters, elements, heat exchangers

We also offer heat exchangers, filters, and filter elements for industrial machinery.

Our high-efficiency, long-lasting products contribute to stable equipment operation and energy savings.

Backed by extensive experience, we support our customers in achieving optimal fluid control and sustainable productivity.

Research and development support equipment

We stock a wide variety of scientific equipment, including testing equipment, laboratory equipment, and various containers.

We provide products essential for research and experiments.

From laboratory equipment to production facilities

Heating and melting equipment and related products

We offer a wide range of heating and melting equipment, from small laboratory equipment to large production facilities.

Over the past few decades, we have built up a track record of supplying a wide variety of industries, including electronics, chemicals, steel, automobiles, aircraft, universities, and government agencies.

We apply the technology and experience we have gained to product development, creating products that meet rapidly changing market needs and delivering higher quality heat treatment furnaces.

We also aim to increase customer satisfaction with our quick response capabilities.

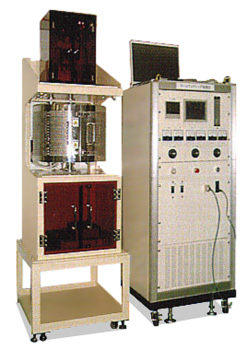

Electric furnace for research and development

We offer a wide range of safe and easy-to-use electric furnaces that are ideal for developing new materials and products. We also customize standard products to meet the diverse needs of our customers.

Production electric furnace

We manufacture fully custom-made equipment to suit your production needs, from large-scale continuous production furnaces to large batch furnaces. We will respond to your requests by leveraging our extensive experience in electric furnace production, so please let us know your requests and requirements.

Glass melting furnace, annealing furnace, molding equipment

We offer a range of equipment, from melting furnaces for glass raw materials, annealing furnaces for the annealing process, and glass forming equipment.We can handle everything from small-scale equipment for research to large-scale production facilities.

Custom-made for each customer

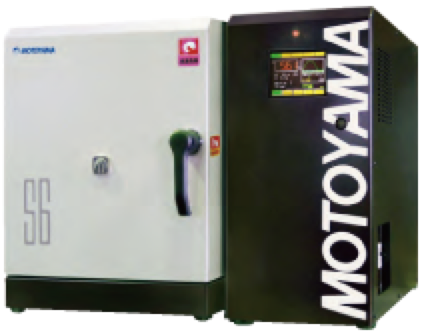

Batch and continuous dryers, waterproof testing equipment

Leveraging the advanced technical capabilities and know-how we have cultivated through our product manufacturing and customization efforts,

we manufacture completely custom-made dryers and waterproofing test equipment for our customers.

Our specialized technical staff will inquire about your industry, factory size, installation requirements, and other details, and will handle everything from design to production and after-sales service.

We will respond to all of your inquiries regarding dryers and waterproofing test equipment with attentive care.

Batch dryer

We manufacture custom-made batch dryers ideal for small-lot, high-mix production in factories.

Using an electrically heated system with a hot air circulation system up to 600°C, we can handle low-oxygen concentration atmospheric treatment and atmospheric/clean specifications, and we can also manufacture door opening and closing mechanisms to suit your needs.

Waterproof test equipment

This test equipment, used to verify the “grade of protective structure provided by the enclosure of electrical appliances” as specified in the JIS standard, is customized to suit the size of the object being tested.

It complies with IPX testing and is compatible with both spray and drip tests.

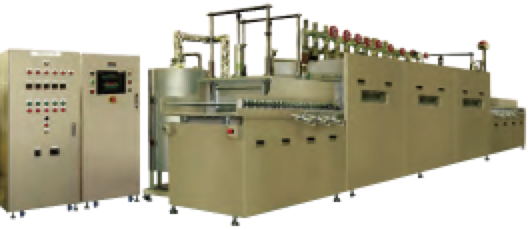

Continuous dryer

We manufacture custom-made continuous dryers that can continuously heat-treat large quantities of products.

They use an electric heating system with a hot air circulation structure up to 500°C, and are compatible with atmospheric treatment and air/clean specifications. We also manufacture inline structures with upstream and downstream machines, including conveyors.

Realizing our ideals by leveraging the characteristics of a multi-faceted company

Our combined marketing strategy, leveraging our thermal, measurement, and control technologies, has enabled us to develop next-generation markets and integrate technologies from multiple industries.

We offer a wide range of products through our combined manufacturing and trading capabilities

In addition to manufacturing and selling our own products as a manufacturer, we also handle a wide range of manufacturer's products as a trading company. When it comes to "thermal application technology" and the associated measurement and control equipment, you can rely on us. We will quickly propose and deliver products that meet your needs.

Trading company functions combined with advanced knowledge and technical capabilities

A major feature of our company is that each employee in each department has in-depth knowledge and technical expertise regarding the product group they are in charge of. Even when delivering products as a trading company, salespeople who are familiar with the products work together with specialized engineers to select and deliver the right products and provide after-sales support.

Quickly dispatch employees to domestic and overseas sites

Our company handles only highly specialized products related to thermal application technology. Therefore, our employees who are familiar with the products will directly visit the site, not only in Japan but also overseas, to handle the delivery and installation of the products, as well as maintenance in the event of an emergency.