[NIKKATO CORPORATION Product]

Wear-Resistant Ceramics Zirconia Balls for Milling, Dispersion, and Mixing

Zirconia ball

Zirconia balls are highly wear-resistant and durable milling and dispersion media, characterized by their high density, superior strength, high toughness, and fine-grained microstructure.

IIn addition to these superior properties, zirconia balls offer high milling and dispersion efficiency, which allows them to meet the following powder characteristics required for high-performance materials:

・Submicron particle sizes

・Sharp particle size distribution

・Minimal/No harmful impurities from contamination

・Superior quality stability

No harmful impurities due to contamination, and excellent quality stability.

They are already highly regarded for delivering high quality and productivity in fields such as ceramics, electronic component materials, inks, and paints.

Zirconia Ball

Features

- Extremely low wear loss and long service life contribute to significant cost reduction.

- High milling efficiency shortens processing time, thereby increasing productivity.

- High abrasion resistance minimizes the introduction of impurities into the material being milled/dispersed.

- Their high sphericity, smooth surface finish, and sharp size distribution enable high-precision milling and dispersion.

- High strength and toughness minimize cracking and chipping from impact, making them compatible with various milling machines, including bead/media mills.

- They are highly effective for high-viscosity wet milling and dispersion processes.

Main applications

For grinding and dispersing various materials

- Electronic component materials such as dielectric, piezoelectric, and magnetic materials

- Phosphors, electrode materials for batteries

- Fine abrasive powders, CMP abrasive grains, etc.

- Pigments, paints, and coatings

- Pharmaceuticals, agrochemicals, powdered food products

- Fine Ceramic Materials

Media for blasting and shot peening, and heat treatment bedding powders

Properties (Typical Values)

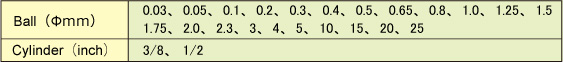

Size