Equipment Overview

- This is the most common double-door heat treatment furnace for production use.

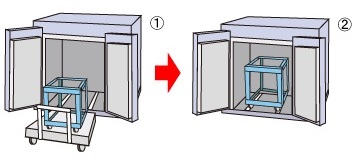

- This system uses a parent-child cart system. The cart for installation in the chamber is placed on top of the cart, and after the sample is set outside, it is carried to the front of the system and only the child cart is placed in the chamber. Only the child carts are placed in the chamber. The inside of the chamber is guided by guide rails so that the specimens can be placed in position.

- Equipped with a cooling blower, the temperature drop time is shortened compared to a conventional incubator, thereby increasing the number of processes.

Main applications

Heat treatment of heavy materials, etc. Teflon baking, carbon, moisture drying, drying of paint.

Features

- Parent-child cart system

Since the child cart can be loaded and unloaded even when the inside of the furnace is not completely cooled, the work time can be shortened by loading and preparing workpieces on the child cart for replacement. - Reduced rise in surface temperature

Slits are placed at the top and bottom of the door front to suppress the rise in surface temperature.

Max. temperature 150°C

Slit for hand lifter is provided at the bottom of the machine.

A slit for a hand lifter is provided at the bottom of the machine.

| Equipment Specifications | |||||

| Item | Description | ||||

| Product name | Double-door incubator | ||||

| Method | Hot air circulation method | ||||

| Temperature range | RT+40°C to +400°C | ||||

| Inner dimensions of furnace | W1600×H1400×D1000 mm | ||||

| Outside dimensions | W2400 x H2000 x D1500 mm | ||||

| Accessories | Parent and child cart | ||||

These are basic specifications. We will design and manufacture according to your company’s conditions of use.