Equipment Overview

This is an electric furnace for laboratory use that combines a rotary kiln, which is effective in heating samples evenly and shortening firing time, and a transparent electric furnace with energy-saving design and good response in heating and temperature drop. The compact design of the furnace makes it ideal for use in various tests and R&D activities.

Features

- The rotary kiln performs heating while rotating the core tube, thus ensuring uniform firing of powder samples.

- The stirring effect of the sample reduces firing time and power consumption.

- Automation of sample loading and unloading contributes to simplification of the work process.

- Firing conditions (temperature, residence time, flowability, etc.) can be found and reflected in a continuous mass production furnace.

- The electric furnace is shielded and insulated by gold mirrors that reflect more than 95% of the heat rays from the heater.

- The thermal capacity of the insulation is much smaller than that of conventional ones, and it has excellent heating and lowering temperature characteristics.

- A thin gold mirror easily provides long heat equalization characteristics, even with a single heating element.

- The furnace interior can be observed from temperatures around 650°C due to the illumination effect of the red-hot heaters.

- A small amount of sample can be fired while observing inside the furnace.

- Furnace body and control unit are integrated into a single structure for tabletop use.

- By closing both ends of the core tube, it can be set to a simple atmosphere specification, making it easy to conduct experiments in various atmospheres.

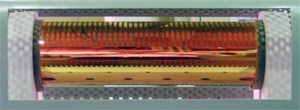

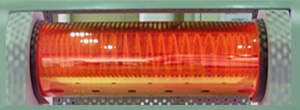

The surface remains golden brown.

The inside of the core tube can be observed.

option

Rotary Joints

| Equipment specifications RK-0330 | |

| Main unit dimensions | W750×H570×D400mm (including cover) |

| Max. temperature | 900°C |

| Core tube dimensions | φ36×φ32×L700mm (made of transparent quartz) |

| Heating element | Sheathed metal heater |

| Heating element capacity | 1.43kW |

| Rotation speed | 1 to 10 rpm continuously variable |

| Control method | PID continuous control method |

| Primary power supply | AC200V 1φ 50/60Hz 2.8kVA |

| Weight | Approx. 45kg |

| Standard accessories | 1 core tube, 1 inner case |