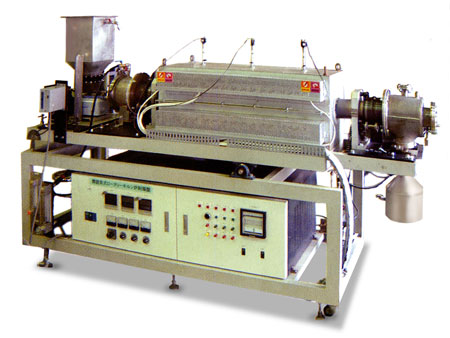

Equipment Overview

This rotary kiln is designed for firing large quantities of samples for production use. By attaching an auto feeder, samples can be fed continuously. The electric furnace section is controlled by three circuits, allowing for a long even heating length.

forte

- The rotation speed and inclination of the core tube can be varied as desired, and the feed rate and residence time can be adjusted.

- The core tube can be easily replaced according to the shape of the sample and the atmosphere inside the furnace.

- Duplex type is also available according to production volume.

- The furnace section is split in two, allowing easy replacement of the core tube.

- It saves space and energy in production.

- Stable sample supply is made possible by a unique fixed-volume feeder.

Continuous Rotary Kiln

By attaching a sample hopper and feeder and automating the loading and unloading of samples, the system can operate unattended 24 hours a day.

| Continuous Rotary Kiln | ||

| Atmospheric Specification | Atmosphere specification | |

| Atmosphere | Atmosphere (oxidizing atmosphere) | Atmosphere (atmospheric and gas atmosphere) |

| Rotation speed | 1 to 10 rpm | |

| Heating element | Silicon carbide heating element | |

| Heating element capacity | 16 kW (3 zones of 4, 8, and 4) | 16 kW (3 zones of 4, 8, and 4) |

| Heating chamber dimensions | W200 x H250 x L1000mm | W200×H250×L820mm |

| Furnace opening dimensions | φ120mm | |

| Furnace core tube dimensions | φ110×φ95×L1900mm | φ114.3×φ98.3×L1780mm |

| Maximum temperature | 1500°C | 1400°C |

| Normal operating temperature | 1400°C | 1300°C |

| Control method | PID continuous control method | |

| Furnace tube Material | Usable temperature | Atmosphere | ||

|---|---|---|---|---|

| Metal | Stainless steel | SUS310S, SUS316L, etc. | ~Up to 1000°C | Possible |

| Inconel | High Ni-High Cr alloy | ~Up to 1000°C | Permissible | |

| Nickel | —Nickel alloy | 1000℃~1000 | Permissible | |

| Ceramic | Porous mullite | Equivalent to the maximum furnace temperature | Not possible | |

| Porous high purity alumina | Not available | |||

| Micro dense mullite | Possible | |||

| Micro dense alumina | Permissible | |||

| High purity alumina | Possible | |||

*We can also manufacture products with temperatures other than the above.