Equipment Overview

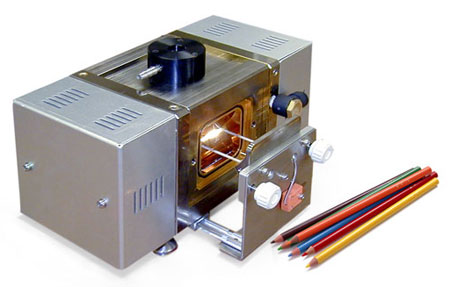

This is an electric furnace with a condenser heating system that allows rapid heating and cooling of samples at ultra-high temperatures with simple operation, as well as high-temperature observation in a vacuum, gas atmosphere, or air.

Features

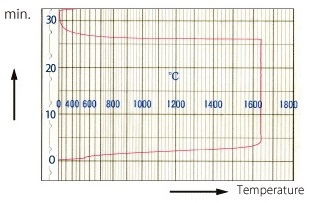

- Rapid heating and cooling to ultra-high temperatures

Gold-plated mirror finish inside the furnace chamber and airtight structure. - Heating in a clean atmosphere

No particle-producing insulation materials in the furnace - Observation of samples at high temperatures

Observation of high temperature behavior of workpieces even at temperatures above 1500°C - Real-time temperature control

Captures workpiece temperature and feeds it back to temperature control Real-time temperature control (PV value = sample temperature) - Energy-saving and space-saving.

Set on a desk, no extra space required

option

- Atmosphere control unit

Easy vacuum evacuation, gas displacement, and gas flow - High-temperature observation unit (x20 to x850 depending on application)

Set of zoom lens and stage for high temperature observation - Dedicated temperature control unit

PID continuous control method with programmed controller - Dedicated Application Software

Simultaneous recording of high temperature images captured by a video camera, temperature and time is possible.

Temperature Control Unit

- Compact design

- Current feedback type PID continuous control method with program controller and thyristor

- With automatic and manual operation switching

- Built-in dedicated alarm circuit

Main applications

| High-Speed Heat Treatment | High-speed heat treatment, thermal cycling, and thermal shock testing of various metallic materials |

| High temperature observation | High temperature in-situ observation, high temperature behavior, reaction observation Contact angle, wettability measurement, |

| Super Image Furnace Specifications | ||

| Model | SVF-QP1-4 | SVF-QP2-6 |

| Maximum temperature | 1700°C | |

| Furnace Structure | 4-elliptical shared light-concentration tube furnace | |

| Atmosphere * | Atmosphere, vacuum (up to 1200°C), gas atmosphere | |

| Sample Exchange Port | 52 x 40 mm | 100×44mm |

| Heating length | 110mm | 210mm |

| Equal heating zone | 10-15mm dia. x L35mm | 10-15mm dia. x L100mm |

| Lamps used | 1kW x 4 | 1.5kW x 4 |

| Cooling water | 4L /min or more | 6L /min or more |

| Vacuum exhaust port | 1/4 Swagelok (Rear) | NW16 (Side: OP) |

| Thermocouple airtight port | 2 locations on the sample exchange port | |

| Specimen holder * | Platinum W10 x L32 x H4mm | To be discussed separately |

| Equipment power supply | 1φ 200V 25A | 1φ 200V 35A |

| Temperature control method | PID continuous control with program controller Manual/automatic changeover, ammeter, various switches, safety circuit |

|

*Vacuum, gas atmosphere and sample holder are optional.