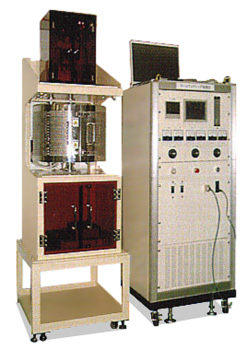

Equipment Overview

This is a device for measuring the viscosity of glass in the strain point and slow cooling point regions, and complies with ISO 7884/4 and 7884/7 by employing the beam bending method, which is specified in the JIS standard “JIS R-3103-2, Method for measuring slow cooling point and strain point by fiber stretching method.

Features

- Automatic operation and data processing by PC.

- The measuring fixture is made of fused fused silica glass, and errors due to thermal expansion are compensated for by data processing software.

- Displacement is read under constant load by a servo mechanism.

| Specifications | |

| Viscosity Measurement Range | Slow Cooling Point, Strain Point, and Range of Viscosity of Glass |

| Electric Furnace | Shape: Twice split front open/close type |

| Furnace Body Dimensions: 450mm dia. x 350mm H | |

| Inner Dimension of Furnace: φ100×H150mm | |

| Maximum Temperature: 1000°C | |

| Heater: Kanthal AF | |

| Heater Capacity : 2.5KW | |

| Loading mechanism | AC servo motor |

| Load cell | Load cell 1Kg |

| Displacement measurement | By pulse position control of servo motor |

| Control panel | External dimensions: W500×H750×D500mm |

| Control method:3-division control byprogram controller | |

| Sequencer: Measurement operation instructions and monitoring by touch panel | |

| PC system | Notebook PC, A4 printer, software for measurement operation and data processing |

These specifications are subject to change for improvement.

Please feel free to contact us for more information about our glass testers!