Feature

Developed for heat treatment processes in general applications

- No external standard pole introduction air is required

- Also available for electric furnace type for vacuum

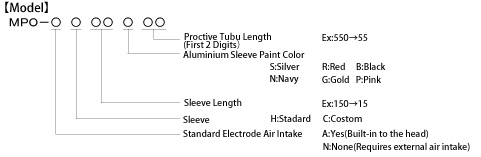

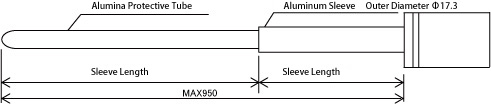

- Various sensor lengths can be selected (Max 950mm)

- High reliability and quality stability

- Products are accompanied by verification measurement data (All products are inspected for accuracy)

Basic Specifications

| Measuring Cell | Stabilized Zirconia Cell Solid Electrolyte |

| Thermocouple | JIS(R) |

| Measuring temperature range | 750 to 1400°C |

| Measuring concentration range | 1 to 10-20atmPO2 |

| Output signal | DC voltage: 0 to 1500 mV. Temperature: 0 to 1760°C |

| Measurement accuracy | Within ±5mV |

| Utility | 24V DC 50mA (for standard pole introduction air) |

Usage

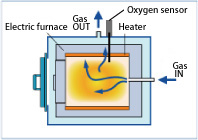

- Measurement of oxygen partial pressure in furnaces during heat treatment in high-temperature atmospheres, such as ceramic sintering furnaces and vacuum furnaces

- Optimize control and adjustment of oxidizing and reducing gas quantities in bright heat treatment of metals

- By adopting it for industrial kilns, boilers, and firing furnaces for production lines that consume a large amount of energy, it contributes to improved combustion control and energy conservation.

field of use

- electronics

- Heat treatment of metal materials and products

- Environment and Energy

- Steel related

- chemical industry

- Industrial Gas Plants

- Nonferrous metal and ceramic firing

- Ceramics & Glass

- boiler

z Please feel free to inquire about special shapes, fixing methods, and anything else you may need.

Use Cases

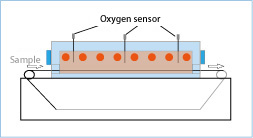

Measurement of oxygen concentration during firing and heat treatment of samples in various gas atmospheres.

0 Batch furnace

0 Continuous furnace