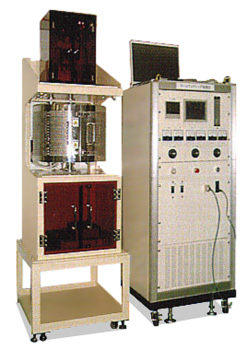

Superheated steam experimental furnace *Patented

Equipment Overview Highly efficient degreasing using superheated steam Proposal of binder removal method The typical degreasing process in the manufacturing process of ceramics requires a slow temperature rise and fall and a long heating time. Therefore, a large amount of energy is consumed in this degreasing process. The use of superheated steam suppresses the rapid […]

Superheated steam experimental furnace *Patented read more »