[ TAISEI KOGYO CO., LTD. Products ]

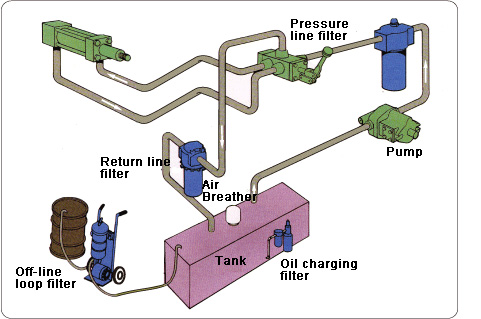

Applications of Various Filters in Hydraulic Systems

○ Flushing

- Removes particles that could cause serious failures in hydraulic systems.

- Removes particles that could cause serious failures in hydraulic systems.

- Extends the service life of existing filters.

Pressure filter

- Prevents pump-generated particles from entering the main system.

- It acts as a ‘last-chance’ filter, removing destructive debris in the event of a major pump failure, thereby protecting downstream components.

Return line filter

- Removes particles generated by internal components and contaminants entering from the outside.

- Improves overall system fluid cleanliness.

Air breather

- Installed on the reservoir tank to prevent external contamination from entering as air is drawn into the tank.

- Some models also incorporate a refueling port.

- Select units with high collection efficiency and appropriate porosity.

Off-line filter

- Used when the inline filter’s flow rate is insufficient to maintain the required cleanliness level.

- Ideal for systems where inline or return line filters cannot be adequately pressurized or are impractical to install.

- Essential for maintaining cleanliness in systems with a high rate of contaminant ingression.

Protection filter

- Installed immediately upstream of components highly sensitive to contamination (e.g., servo valves).

- Reduces component wear.

- Ensures stable valve operation.

- Prevention of system damage (Installation of non-bypass type filters)

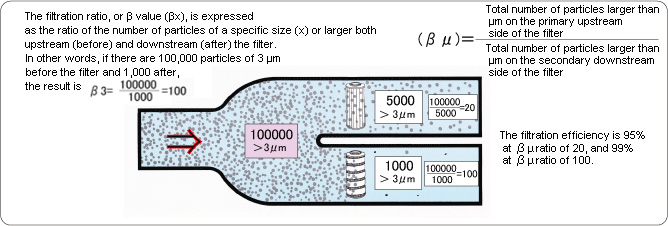

Beta value, filtration efficiency

For inquiries about hydraulic filters and oil coolers, please feel free to contact us at Motoyama!

Our professional staff with expertise will propose hydraulic products that meet your needs and equipment specifications.