[JFCC’s Practical Standard Material]

Universal Thermal History Sensor REFARTHERMO® (REFERTHERMO®)

The firing process in ceramic manufacturing is critical for controlling the material’s properties.

Simply monitoring the firing temperature and heating time is not enough to accurately assess the actual thermal history experienced by the sample.

REFERTHERMO® is a common thermal history sensor designed to easily and accurately determine the overall thermal history required for precise process control.

We are an authorized agent for the Japan Fine Ceramics Center (JFCC), offering this highly effective thermal history sensor.

Principle of REFERTHERMO®

REFERTHERMO® is a compact, shaped ceramic component made from a powder blend primarily composed of alumina.

Standard ceramics undergo shrinkage and densification when heated, eventually becoming a dense body.

As a Practical Reference Material, it functions as a thermal history sensor by utilizing the phenomenon of highly reproducible shrinkage and densification under specific firing conditions.

How to Use REFERTHERMO®

Place the RIFATHERMO® in the same location as the product to be fired inside the heating equipment (e.g., firing furnace).

After firing, measure its resultant dimensions. The thermal history can then be determined using a reference table.

Features

The sensor itself is manufactured by strictly controlling the composition, particle size, and molding density of the raw materials, and has extremely high reproducibility in terms of thermal history and shrinkage dimensions during firing.

Firing conditions can be shared among multiple heating systems, enabling mutual sharing of technical data and comparative evaluation.

By using the system continuously on a regular basis, it can be applied to control abnormalities in firing furnaces and statistical quality control.

Applications

Firing control and Statistical Quality Control (SQC) for materials such as fine ceramics, electronic ceramics, and pottery products.

Used for confirming the reproducibility of thermal history and verifying temperature uniformity within electric furnaces and firing furnaces.

Important Notes

- When REFERTHERMO® is used in a vacuum or a low-oxygen atmosphere, some of its components may evaporate and cause contamination inside the furnace.

Additionally, the degree of shrinkage can vary depending on the ambient atmosphere. - The indicated value of REFERTHERMO® is not the actual physical temperature (e.g., the temperature displayed by a controller), but rather an indicator representing the overall thermal history experienced by the sensor placed at the control point.

- When selecting a sensor, please note that differences may arise not only due to the applicable temperature range but also the duration of the holding temperature.

Therefore, please consult with us before final selection and adoption. - For further details, please refer to the User’s Manual.

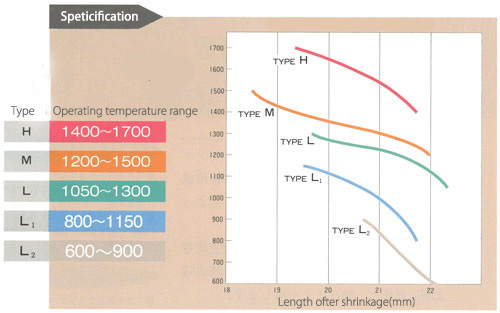

Operating Temperature Range and Indicated Temperature Accuracy of REFERTHERMO®

| Type (Abbr.) | Operating Temperature Range | Indicated Temperature Accuracy |

|---|---|---|

| H | 1400 to 1700°C | 10°C ±10°C |

| M | 1200 to 1500°C | M 1200 to 1500°C ±10°C |

| L | 1050 to 1300°C | 10°C ±10°C |

| L1 | 800 to 1150°C | 15°C ±15°C |

| L2 | 600 to 900°C | 15℃ ±15℃ L2 |

Specification Temperature Characteristics Table

☆ Thermal history sensor REFERTHERMO® is an authorized product distributed by the Japan Fine Ceramics Center (JFCC).