Heaters for Electric Heating

[YOSHIOKA CO.,LTD. Products]

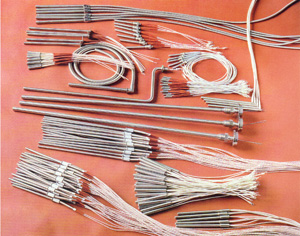

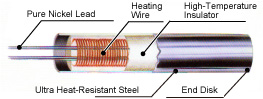

Compact and Highly Durable Cartridge heater

Cartridge heater

Cartridge heaters are shaped like a pipe with a lead wire extending from one end, and provide effective heating when inserted into the object to be heated.

The specially filled heaters are compressed until the internal insulating material no longer breathes, making them resistant to vibration shock.

Even in high-temperature dry-fire durability tests, they withstood long-term continuous use at a surface temperature of 800℃.

They are primarily used as a heat source for electric heating platens in presses, molding machine dies, and various automated equipment.

They can also be adapted for liquid heating through welding processes, such as adding bushings.

Features of Cartridge Heaters

①High quality high wattage cartridge heaters have very high insulation properties at high temperatures.

②Long heater life ensures reliable and safe operation.

③Insulation is designed to withstand Japan’s environment, characterized by high temperatures and high humidity.

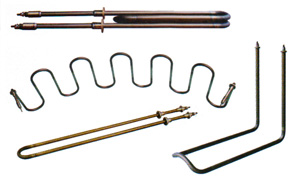

Sheathed Heaters: Versatile and Excellent in Electrical Insulation

Sheathed Heaters

Sheathed heaters are used for direct heating and also serve as the base element for cast-in heaters, far-infrared heaters, immersion heaters, and other applications.

The surface temperature of the heater’s sheath pipe can be manufactured for up to 850℃.

The heater sheath is completely electrically insulated.

Safe operation is ensured by taking proper precautions with the connection terminals.

The heater sheath material can be selected for optimal use, including copper, steel, stainless steel, Incoloy, and others.

Sheathed heaters can be fitted with fins to increase the heat transfer area.

These finned heaters are used in packaged heaters for air conditioning and heating, warm air heaters, and other applications that require a large heat source in a relatively small space.

Sheathed heaters can be manufactured in a variety of configurations, from straight elements to complex, custom shapes.

Additionally, we manufacture Teflon-coated heaters, offering excellent chemical resistance for use in heating corrosive chemicals.

The photo on the left shows a heater for heating air or other gaseous substances in a high-temperature hot air heater.

The photo on the right shows a Teflon-coated sheath heater.

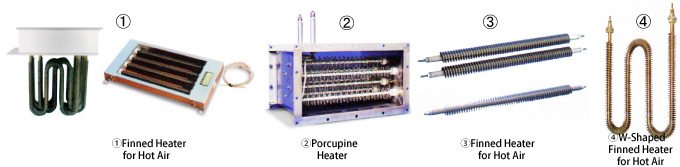

Heater for hot air generation Optimized for Specific Equipment and Installation Sites

Electric hot air heaters are gas heating elements based on the application of metal tubular heaters and Porcupine-type heaters.

These heaters feature thin, highly heat-dissipating stainless steel fins attached to the outside of the element and are used as heat sources for hot air generators, dryers, and duct applications, delivering the precise heat output required for each specific location.

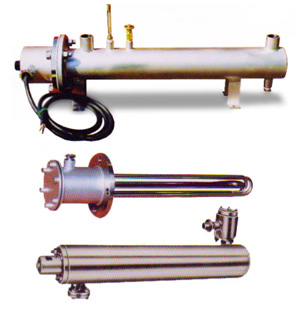

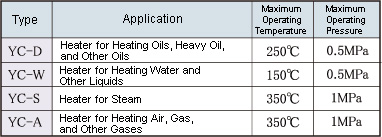

Circulation Heater for Fluid and Gas Flow Circulation and Superheating

Circulation heaters integrate immersion heaters to heat liquids and gases during forced circulation. They are designed and manufactured to heat various fluids, including water, oil, solvents, and solutions, as well as steam, air for drying, preheating, and sintering, and other gases directly within the pipeline.

Due to their design, they are easy to install and operate, allow for temperature adjustment, and can be equipped with a dry-fire prevention control (over-temperature controller) to safeguard the heating element from damage.

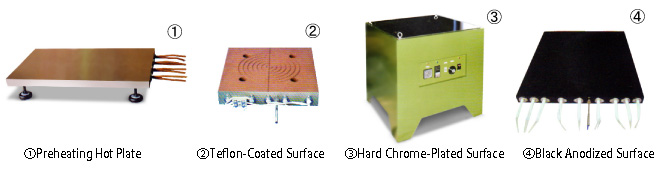

Robust Hot Plates with Superior Surface Precision

[Features]

- Precision Hot Plates are robust heating plates manufactured as single-piece units using machining (cutting) processes, resulting in superior surface flatness and precision.

- Plate materials include stainless steel and aluminum, making them suitable for use in cleanroom environments.

- Hot plates are available in two types: those with inserted cartridge heaters and those with cast-in sheathed heaters.

Their structure is robust enough for use in hot presses and to withstand high pressure. - We can also manufacture custom-made products tailored to various applications and specific heating requirements.