<To be eligible for free Refatherm

○ The existing 5 types (Type H~L2) of Refatherm are to be considered.

The number of Refasermo used in a test must be less than 10 cases.

○ First time users who are considering using Refasermo for the first time.

Please fill out the questionnaire.

Common thermal history sensor Refatherm

JFCC RMs

The firing process in the manufacture of ceramics is critical to the control of their properties.

Simply monitoring and measuring firing temperatures and heating times is not enough to manage the exact thermal history added to a sample.

Refatherm is a common thermal history sensor to easily and accurately determine the overall thermal history for process control.

We sell this excellent thermal history sensor as a distributor of JFCC.

Principle of Refatherm

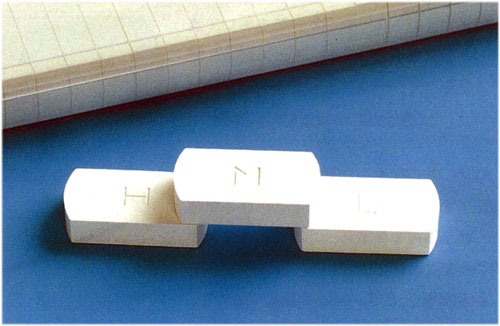

Refatherm is made of ceramic powder mainly composed of alumina, etc., molded into a specified shape.

General ceramics shrink and densify under elevated temperature conditions, eventually forming a dense body.

As a practical standard material, RIFATHERM is a thermal history sensor that utilizes the phenomenon of shrinkage and densification with good reproducibility under firing conditions and thermal history.

How to use Refatherm®.

By placing the REFERTHERM in the same location as the fired product in a heating device such as a firing furnace and measuring the fired dimensions after firing, the thermal history can be measured from a control table.

forte

The sensor itself is manufactured by strictly controlling the composition, particle size, and molding density of the raw materials, and has extremely high reproducibility in terms of thermal history and shrinkage dimensions during firing.

Firing conditions can be shared among multiple heating systems, enabling mutual sharing of technical data and comparative evaluation.

By using the system continuously on a regular basis, it can be applied to control abnormalities in firing furnaces and to statistical quality control.

Click here for detailed specifications

Click here to contact us.