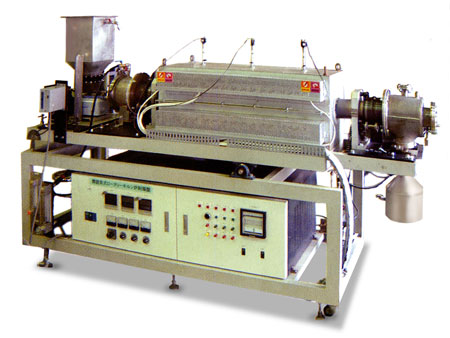

Atmospheric Fast Heating Electric Furnace NLA/NHA Series

Equipment Overview The atmospheric type high speed heating electric furnace is an electric furnace equipped with a gas-filled mechanism that allows firing or heat treatment of samples in various gas atmospheres, such as air, nitrogen (various gases as an option), or various gas mixtures. This furnace can be used as a multipurpose research and production […]

Atmospheric Fast Heating Electric Furnace NLA/NHA Series read more »