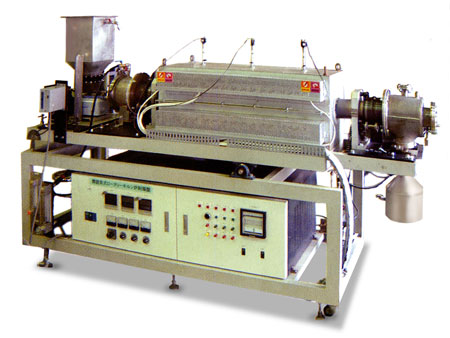

Atmosphere-supporting Continuous Rotary Kiln

Equipment Overview This rotary kiln is designed for firing large quantities of samples for production use. By attaching an auto feeder, samples can be fed continuously. The electric furnace section is controlled by three circuits, allowing for a long even heating length. forte Continuous Rotary Kiln By attaching a sample hopper and feeder and automating […]

Atmosphere-supporting Continuous Rotary Kiln read more »