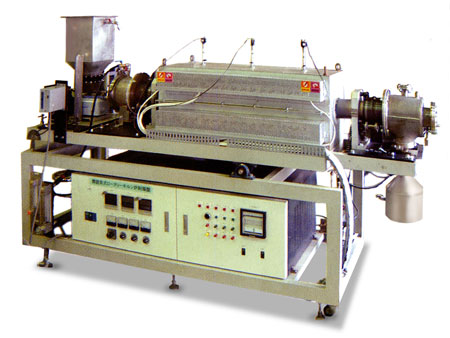

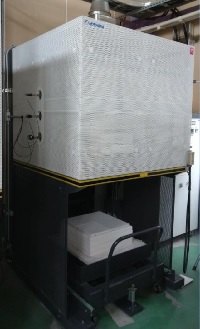

Oxidizing Atmosphere Ultra High Temperature Electric Furnace KB/KL Series

Equipment Overview The KL/KB series of small electric furnaces are super high-temperature electric furnaces with lanthanum chromite Keramax unit heaters as heating elements.Two types are available: KL (max. temperature 1900°C) and KB (max. temperature 1800°C). KL uses alumina refractory for insulation, while KB uses alumina board. Both KL and KB are designed to take advantage […]

Oxidizing Atmosphere Ultra High Temperature Electric Furnace KB/KL Series read more »